coal handling plant Péroupedia

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011.1.1 Compared with actual situation of the current thermal power plant, this paper studies operation process of coal handling system in thermal power plant. Analyze

More

Coal handling plant in a thermal power generating

2024.1.1 Introduction to Coal handling plant. In a coal based thermal power plant, the initial process in the power generation is “Coal

More

Coal Handling System of Power Plant Based on PLC - Springer

2020.11.5 The main task of this design is to process coal from coal source into pulverized coal and supply it to the original coal bunker for combustion and power

More

FMEA and FTA of coal handling system of power plant

2023.1.1 The main sub-systems of the coal handling plant are wagon tipplers, Belt conveyors, Coal Crushers, and drive units. The coal is received by railways or large

More

FMEA and FTA of coal handling system of power plant

2023.1.1 In a power plant, there are many important sections such as the Turbine section, Boiler section, Coal Handling Unit, Ash Handling Unit, Generator unit, etc. In this

More

(PDF) Automation of Coal Handling Plant

2010.1.1 In this paper an integrated solution of coal handling plant is given to meet the increasing production needs. The VERSA-PRO software is used to develop the ladder logic. This paper only...

More

Quantifying operational lifetimes for coal power

2019.10.18 A rapid transition away from unabated coal use is essential to fulfilling the Paris climate goals. However, many countries are actively building and operating coal power plants.

More

VWHPRI7KHUPDO3RZHU3ODQW - IOPscience

reduction in coal handling system of thermal power plant was advised, which provides reference for dust control in coal handling system 1. Introduction Thermal power

More

VLVRI)LUHVLQRDO3RZHU3ODQWV

1. Introduction The Coal Handling facility at the coal-fired power plant is a major system used to handle coal from receiving coal from shipping ships from coal mines and then

More

(PDF) Fire Hazards of Coal Storage Sites - ResearchGate

2023.1.5 Coal’s high propensity for spontaneous combustion can be the cause of fires in coal heaps located at mine sites, power plants, distribution or coal handling

More

Coal Handling Plant PPT - SlideShare

2016.6.14 THE ENTIRE COAL HANDLING SYSTEM DIVIDED IN THREE SECTION. 1. CHP-1 situated inside plant boundary, capacity 1500 TPH 2. CHP -2 situated mine end, capacity 1000 TPH 3. CHP-3 Cross

More

(PDF) Investigation of various maintenance

2019.10.21 Investigation of various maintenance parameters for auxiliaries in a coal‐handling plant aided by a Visual Basic 6.0–based scheduled program October 2019 Engineering Reports 1(4)

More

Development of a dust minimization system for the coal

2016.10.16 In a thermal power plant, a coal handling plant entails the initial coal process operations such as unloading, storage, screening and filling into bunkers before the coal is send to the boiler for steam generation. If adequate measures are not taken, the coal handling plant can turn out to be a very dusty environment ( Fox 2012). Enough

More

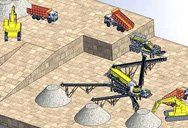

Coal Handling Plant, Equipment, System Manufacturer VG

5 天之前 These plants are equipped with grizley hopper, belt conveyor, crusher, vibrating screen, bucket elevators and other allied equipment that facilitate and expedite the work processes. VG Engineers is a well-known manufacturer of coal handling plants in Gujarat. Our Coal handling system will help you improve your regular production ability and ...

More

Investigation of various maintenance parameters for auxiliaries

2019.10.21 Therefore, the supply of good quality coal in useable form is one of the crucial operations in a thermal power plant. This can be achieved in a coal-handling plant (CHP), which processes coal and supplies it in the required size and quality using its several auxiliaries. 1 Wagons are used for carrying coals from mines to the coal plants where ...

More

Coal Handling in Thermal Power Plant - Deepakkumar Yadav

2021.9.8 Therefore, one of the major requirement of a power plant is to reduce the cost of handling of coal from the point of its origin upto the furnace of boiler where it is burnt. Various steps involved in a coal handling system as shown in Figure A are : Coal delivery. Unloading. Preparation of coal. Transfer of coal. Storage.

More

Quality Circle: Maximizing the Productivity in Coal Handling Plant ...

2022.6.4 Figure 3 shows conveyor pulley in coal handling plant (Ankit Gupta 2013). Why-Why technique is also a problem-solving method to solve problem on work-related which not only upholding the emphasis on the indications but also lead to the root cause of a problem. For that depth of analysis with brainstorming is required to reach out the root

More

Impact of Material Chemistry on the Performance ... - Springer

2019.1.22 The unit numbers are 164 and 165. Dilute Pump. The dilute pump is also important in delivering the working constituents to desired locations along the conveyor belts (Ji-ping 2010a).Figure 3 presents a pictorial representation of the dilute pump at the coal beneficiation plant, with specific unit numbers associated with each pump. Unit numbers

More

Waste Water Management in Super Thermal Power Stations

2020.9.1 Waste water is generated in power plants mainly by way of generation of high TDS blowdown from closed cycle operation of condenser cooling water circuit with cooling tower, wet ash handling, coal water slurry formed as a result of water sprinkling for coal dust suppression in coal handling plant transfer points, crusher house, coal stack

More

Coal handling along the supply chain - ScienceDirect

2023.1.1 The following sections will give some ideas and preselection criteria for choosing the right approaches for coal handling plants in different market segments. 21.2. Conveying. In general, conveying systems connect process or materials handling machines, and are widely used in the industry. An intelligent connection and combination of different ...

More

5-4 - International Nuclear Information System

2010.10.21 The General flow diagram of In-plant coal handling system which is to cater for 3 X 30 MW (E) is shown in Figure No.l. ROM coal transported by ropeway from Manuguru mines to Plant site will be dumped into the underground coal receiving hoppers located at plant site. The conveyor belts and crusher have the capacity to deliver the coal

More

Coal Handling Coal Handling Preparation Plant

The coal handling plant crushes coal into graded sized chunks, stockpiling grades while preparing it for transport to market and, more often than not, loads the coal into rail cars or barges. RPM Solutions services multiple

More

(PDF) Application of Lean Tools in Planned Maintenance

2020.12.7 Figure 4: Coal Handling Plant Planned Maintenance Current State Map Proceedings of the 2nd African International Conference on Industrial Engineering and Operations Management Harare, Zimbabwe ...

More

McNally Bharat Engineering Company Limited

Coal Handling Plants. MBE, the pioneer in Bulk Material Handling Systems, has built over 150 projects ranging from 500 TPH to 20,000 TPH. MBE is proud to have executed the first indigenously built cross country Coal Conveying System and Coal Handling Plant at Talcher Thermal Power Station for Orissa State Electricity Board in 1968.

More

DVVHVVPHQWDQGLPSURYHPHQW

system, turbine system, unit auxiliaries, ash handling plant, pumping system, chiller, cooling tower, air compressor, lighting system, motor load and thermal insulation. Before the assessment of the various systems, the overall efficiency of the plant considered for a period of a year where the maximum efficiency is found to be 37.95% and the

More

Identification Hazards and Risk Assessment in Power

2022.8.10 coal-fired thermal power plants requiring nearly 440 million tons of coal annually [1, 2]. The energy available in the coal is converted into electricity in a coal-fired thermal power plant, and this conversion of coal to electricity takes place in multiple stages. The process begins from coal transportation from the nearby mines, and the

More

Dust removal method of coal-fired power plant based on

2021.8.26 To further enhance the dust removal capacity of coal-fired power plants, a new dust removal method based on micro-power dust removal device for coal-fired power plants was proposed. Based on the physical characteristics of dust removal and dust removal mechanism, the air flow balance of the dust remover was set, and the dust

More

Hazard Identification and Risk Assessment of 2 × 300 MW

2020.10.28 In India, a coal-based thermal power plant generates 93,918.38 MW approximately of total energy production. A coal-based thermal power plant converts the chemical energy of the coal into electrical energy. The company is operating coal-based 2 × 300 MW thermal power plant which is driven by steam and generates electricity by

More

Energy Conservation in Opencast Coal Mining: A Case Study

2015.4.1 The whole system has been designed and tested using G.E FANUC PLC with SCADA. In this paper an integrated solution of coal handling plant is given to meet the increasing production needs. The ...

More

Water Resource Management for Coal-Based Thermal Power Plant

2021.9.21 Water Requirements for coal handling plant varies from plant to plant based on the location of coal storage, numbers of coal Stockpiles, numbers of transfer points. For typical 2 × 660 MW unit, water requirement for coal handling plant is estimated in the range of 100–150 m 3 /h. 3.2.4 Demineralized Water System Water Requirements

More

Modification of Coal Handling System in Boiler Power Plant

2016.3.11 The following equipment used in coal handling plant: In simple coal handling systems following equipment are used in old days. 1. Hopper 2. Vibro-feeder 3. Belt conveyor-1 4. Crusher 5. Belt conveyor-2 6. Bunker 7. Furnace Simple working of coal handling plant: Coal handling is the essential preparation of coal for the feeding coal to

More

Chp in presentation PPT - SlideShare

2012.12.7 3. Wagon Tipplers These are the giant machines having gear boxes and motor assembly and are used to unload the coal wagons into coal hoppers in very less time (e.g.20 wagons/hr. or more) For coal

More

(PDF) REDUCTION OF AUXILIARY POWER THROUGH

2010.11.18 The auxiliary power consum ption of coal handling plant will be in the range of 0.12 – 0.14 % of gross ge neration. The SEC of coal handling plant will vary in the range of 1.1 and 1.6 kWh/t of ...

More

Coal Handling Plant - Coal Handling system Latest Price,

Coal Handling Plant. ₹ 20,00,000/ piece Get Latest Price. Capacity: 5TPH - 50TPH. With the prosperous industry knowledge, our firm is presenting an extensive series of Coal Screening Plant. Our products are developed utilizing the advanced technique and top quality material which is sourced from top.

More

[PDF] OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING

Many utility systems in the world have power plants operating with fossil fuel. In the thermal power plants maximum requirements of fuel is a coal. The handling of this fuel is a great job. To handle the fuel, i.e., coal, each power station is equipped with a coal handling plant. Maintenance of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power

More

(PDF) Operation and Maintenance of Coal Handling System

2011.12.31 Reduction of Auxiliary Power of In-house HT Equipment in Thermal Power Plant by Energy Conservation. January 2015. Rajashekar P. Mandi. Udaykumar R Yaragatti. This paper describes the results of ...

More

Coal handling plant in a thermal power generating station

2024.1.1 In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”. So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station. The huge amount of coal is usually supplied through railways. A railway siding line is taken into ...

More

Chapter 3 Residual Life Assessment - Springer

2017.8.27 Kunze U, Raab S (2012) Assessment of remaining useful life of power plant steam generators—a standardized industrial application. In: European conference of prognostics and health management society 2012 Padole PM, Joshi MM (2002) Application and implementation of residual life assessment techniques for coal handling plant.

More

(PDF) Fire Hazards of Coal Storage Sites - ResearchGate

2023.1.5 The article gives advice on routine maintenance of coal handling equipment and of the use of monitoring and control systems to prevent fire. It sites an incidence of a fire being triggered by the ...

MoreArticle aléatoire

- broyeur de vegeteau proffessionel

- fournisseurs concasseur à mâchoires

- 500 999 moulins en argent fin concasseur

- usine de bloc de pavage en beton

- fabrication un tamis vibrant

- procédNouvelle Caldonia de broyage de cuivre

- broyeurs à marteaux mini

- Machine à meuler HMT

- schema de separation par flottation des minerais

- jual broyeur de pierres indonésie équipements

- monter une usine de fabrication de carton

- los mejores motores del molino posho en venta

- le minerai de fer magnetite malaisie

- minerai dor fournisseur de concasseur a machoires mobile en indonessia

- aspirateur souffleur trimma

- wabeco machine de fraisage f1210e

- taille de l'equipement de concassagemines de cuivre en Afrique

- prix de l hippopotame maïs broyeur au zimbabwe

- prix de concasseur a cone

- Sayaji concassage de pierres machinary en Inde

- liste des broyeur de pierres a raipur chhattisgarh

- broyeur de pierres di tanzanie

- roche et de sable fournitures à Eldoret au Kenya

- usine de meulage de scories cote divoire

- mini pellet mills for sale

- rapport de projet pour les unites de trituration de pierre

- est entreprise concasseur en tanzanie bonne

- interne de la Chine de broyage 2

- concasseur à marteaux évolution

- provenderies de l aquaculture en afrique du sud